Introduce and Installment of Sanitary Butterfly Valves

Release time:[2020-05-28] Click through rate:Sanitary butterfly valves are widely used in food, pharmaceutical, cosmetics, clean steam, alcohol, beverage, biochemical industrial process control occasions. It is a sanitary, automatic or manual operated butterfly valve, suitable for various applications inside the stainless steel piping system.

Sanitary butterfly valves can be operated remotely by a pneumatic actuator or manually by a handle. There are three standard types of sanitary butterfly valve actuators, namely normally closed (NC) type, normally open (NO) type and air / air (A / A) type. The actuator converts the axial movement of a piston into a 90 ° rotational movement of the valve shaft. When the circular butterfly in the valve body contacts the sealing ring of the butterfly valve, the torque of the actuator increases, and the valve is closed. Selecting a different manual operation handle can mechanically lock the valve in the open, closed, intermediate or other positions on.

The installation of sanitary butterfly valves are as follows:

1. Before installation, the pipes and valves need to be cleaned, and there must be no scratches or dirt on the sealing surface to avoid internal leakage or reduce product replacement.

2. During installation, you must carefully check whether the connection model of the clamp is the same. A special seal ring should be installed at the connection between the clamp and the valve to make the connection between the valve and the pipeline reliable. Installation of horizontal pipes and vertical stainless steel angle steel pipes.

3. When the medium is passed through after installation, turn the handle 90 ° to check the inner seal. If there is no leakage, can be used normally.

4. The sanitary butterfly valve is re-inserted and inserted into the medium, and can also be used to adjust the flow, but do not install the valve in a system that requires strict adjustment of the medium's flow.

5. If the butterfly valve is found to be closed during use, there is still leakage inside, and the seal ring must be replaced and re-installed correctly before use.

Butterfly valves usually have the following connection methods:

Sanitary Butterfly Valve Interface-Welded

Welding fusion welding, trowel welding is a manufacturing process and technology for joining metals or other thermoplastic materials such as plastics by means of heating, high temperature or high pressure.

Sanitary stainless steel butterfly valve interface-quick assembly

Quick installation is more convenient

Sanitary stainless steel butterfly valve interface-threaded

The sanitary stainless steel butterfly valve threaded joint refers to the pipe joint with thread, which is the most common pipe fitting in industry and life. cost.

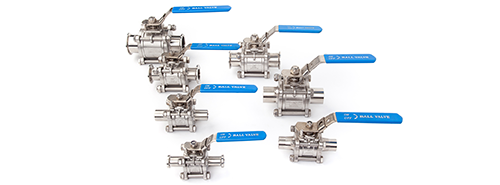

Next message:Sanitary sight cleaning ball